Sheet Glass Manufacture: The Float Process – IELTS Reading Answers

9 min read

Updated On

-

Copy link

Table of Contents

Limited-Time Offer : Access a FREE 10-Day IELTS Study Plan!

Since IELTS Reading is considered the second easiest module of the exam after Listening, solve and review, Sheet Glass Manufacture: The Float Process and similar passages to ensure that your reading skills are up to the mark.

The Academic passage, Sheet Glass Manufacture: The Float Process, is a reading passage that appeared in an IELTS Test. Since questions get repeated in the IELTS exam, these passages are ideal for practice. If you want more practice, try taking an IELTS reading practice test.

The question types found in the Sheet Glass Manufacture: The Float Process passage are:

- Table Completion (Q. 1-5)

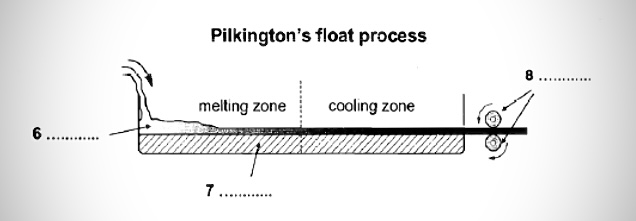

- Diagram Completion (Q. 6-8)

- True/False/Not Given (Q. 9-12)

Reading Passage

Sheet Glass Manufacture: The Float Process

Glass, which has been made since the time of the Mesopotamians and Egyptians, is little more than a mixture of sand, soda ash and lime. When heated to about 1500 degrees Celsius (°C) this becomes a molten mass that hardens when slowly cooled. The first successful method for making clear, flat glass involved spinning. This method was very effective as the glass had not touched any surfaces between being soft and becoming hard, so it stayed perfectly unblemished, with a ‘fire finish’. However, the process took a long time and was labour intensive.

Nevertheless, demand for flat glass was very high and glassmakers across the world were looking for a method of making it continuously. The first continuous ribbon process involved squeezing molten glass through two hot rollers, similar to an old mangle. This allowed glass of virtually any thickness to be made non-stop, but the rollers would leave both sides of the glass marked, and these would then need to be ground and polished. This part of the process rubbed away around 20 per cent of the glass, and the machines were very expensive.

The float process for making flat glass was invented by Alistair Pilkington. This process allows the manufacture of clear, tinted and coated glass for buildings, and clear and tinted glass for vehicles. Pilkington had been experimenting with improving the melting process, and in 1952 he had the idea of using a bed of molten metal to form the flat glass, eliminating altogether the need for rollers within the float bath. The metal had to melt at a temperature less than the hardening point of glass (about 600°C), but could not boil at a temperature below the temperature of the molten glass (about 1500°C). The best metal for the job was tin.

The rest of the concept relied on gravity, which guaranteed that the surface of the molten metal was perfectly flat and horizontal. Consequently, when pouring molten glass onto the molten tin, the underside of the glass would also be perfectly flat. If the glass were kept hot enough, it would flow over the molten tin until the top surface was also flat, horizontal and perfectly parallel to the bottom surface. Once the glass cooled to 604°C or less it was too hard to mark and could be transported out of the cooling zone by rollers. The glass settled to a thickness of six millimetres because of surface tension interactions between the glass and the tin. By fortunate coincidence, 60 per cent of the flat glass market at that time was for six-millimetre glass.

Pilkington built a pilot plant in 1953 and by 1955 he had convinced his company to build a full-scale plant. However, it took 14 months of non-stop production, costing the company £100,000 a month, before the plant produced any usable glass. Furthermore, once they succeeded in making marketable flat glass, the machine was turned off for a service to prepare it for years of continuous production. When it started up again it took another four months to get the process right again. They finally succeeded in 1959 and there are now float plants all over the world, with each able to produce around 1000 tons of glass every day, non-stop for around 15 years.

Float plants today make glass of near optical quality. Several processes – melting, refining, homogenising – take place simultaneously in the 2000 tonnes of molten glass in the furnace. They occur in separate zones in a complex glass flow driven by high temperatures. It adds up to a continuous melting process, lasting as long as 50 hours, that delivers glass smoothly and continuously to the float bath, and from there to a coating zone and finally a heat treatment zone, where stresses formed during cooling are relieved.

The principle of float glass is unchanged since the 1950s. However, the product has changed dramatically, from a single thickness of 6.8 mm to a range from sub-millimetre to 25 mm, from a ribbon frequently marred by inclusions and bubbles to almost optical perfection. To ensure the highest quality, inspection takes place at every stage. Occasionally, a bubble is not removed during refining, a sand grain refuses to melt, a tremor in the tin puts ripples into the glass ribbon. Automated on-line inspection does two things. Firstly, it reveals process faults upstream that can be corrected. Inspection technology allows more than 100 million measurements a second to be made across the ribbon, locating flaws the unaided eye would be unable to see. Secondly, it enables computers downstream to steer cutters around flaws. Float glass is sold by the square metre, and at the final stage computers translate customer requirements into patterns of cuts designed to minimise waste.

Book a FREE Trial Session with Our IELTS Experts to Learn More Tips and Techniques for IELTS Reading!

Questions 1-8

Complete the table and diagram below. Choose NO MORE THAN TWO WORDS from the passage for each answer.

Write your answers in boxes 1-8 on your answer sheet.

| Method | Advantages | Disadvantages |

| 1. _________________ | Glass remained

2. ______________ |

Slow

3.___________ |

| Ribbon | Could produce glass sheets

of varying 4. __________ Non-stop process |

Glass was 5. ___________

20% of glass rubbed away Machines |

Questions 9-12

True if the statement reflects the claims of the writer

False if the statement contradicts the claims of the writer

Not Given if it is impossible to say what the writer thinks about this.

9. The metal used in the float process had to have specific properties.

10. Pilkington invested some of his own money in his float plant.

11. Pilkington’s first full-scale plant was an instant commercial success.

12. The process invented by Pilkington has now been improved.

Want to improve your IELTS Academic Reading score?

Sheet Glass Manufacture: The Float Process Reading Answers With Location and Explanation

Read further for the explanation part of the reading answer.

- Answer: Spinning

Question type: Table Completion

Answer Location: Paragraph 1

Answer explanation: In the passage, it is mentioned that the first successful method for making clear, flat glass involved spinning. The advantage was that the glass remained perfectly unblemished.

- Answer: (perfectly) unblemished

Question type: Table Completion

Answer Location: Paragraph 1

Answer explanation: Spinning was effective in keeping the glass perfectly unblemished, as mentioned in paragraph 1.

- Answer: Labor-intensive

Question type: Table Completion

Answer Location: Paragraph 1

Answer explanation: Spinning was a labour-intensive method, as indicated in paragraph 1.

- Answer: Thickness

Question type: Table Completion

Answer Location: Paragraph 2

Answer explanation: “This allowed glass of virtually any thickness to be made non-stop, but the rollers would leave both sides of the glass marked, and these would then need to be ground and polished.” Hence, the advantage is that it could produce glass sheets of different thickness levels.

- Answer: Marked

Question type: Table Completion

Answer Location: Paragraph 2

Answer explanation: The answer is inferred from the context of the passage. In paragraph 2, it is stated that the previous ribbon method using rollers left both sides of the glass marked.

Unlock Explanations

If you want to have a look at the remaining explanations, sign up!

- Answer: molten glass

Question type: Diagram Completion

Answer Location: Paragraph 4

Answer explanation: The flat and horizontal surface of the molten metal, governed by the theory of gravity, is crucial to the creation of the glass sheet. As the molten glass is poured over the molten tin, its underside is expertly flattened.

- Answer: tin/metal

Question type: Diagram Completion

Answer Location: Paragraph 3

Answer explanation: According to Pilkington, the ideal metal for producing flat glass through the use of molten material would be Tin, and he had devised a plan to implement this method.

- Answer: rollers

Question type: Diagram Completion

Answer Location: Paragraph 2

Answer explanation: To implement the continuous ribbon method, the molten glass needs to undergo squeezing between two heated rollers, which consequently leave markings on both sides of the glass. Following this, the glass is grounded and polished.

- Answer: True

Question type: True/False/Not given

Answer Location: Paragraph 3

Answer explanation: The passage mentions that the metal used in the float process had specific properties, such as melting at a lower temperature than the hardening point of glass and not boiling below the temperature of molten glass.

- Answer: Not given

Question type: True/False/Not given

Answer Location: Paragraph 5

Answer explanation: The passage doesn’t provide information about whether Pilkington invested his own money in the float plant.

- Answer: False

Question type: True/False/Not given

Answer Location: Paragraph 7

Answer explanation: The passage mentions that it took time and a significant cost for the plant to produce usable glass. It was not an instant commercial success.

- Answer: True

Question type: True/False/Not given

Answer Location: Paragraph 1

Answer explanation: The passage mentions that float glass production has continued and improved since its invention by Alistair Pilkington in the 1950s.

Tips for Answering the Question Types in the Sheet Glass Manufacture: The Float Process Reading Passage

Let us check out some quick tips to answer the types of questions in the ‘Sheet Glass Manufacture: The Float Process’ Reading passage.

Table/Note Completion:

Table/Note completion in the IELTS Reading test is quite simple: because of the arrangement and keywords, you may often discover solutions quickly.

To answer completion questions, you can use the following strategies:

- Locate the paragraph containing the keyword

- To discover the keywords quickly, use capital letters, numbers/dates, or italics.

- To discover the statement, look for synonyms or paraphrased words.

- Copy the answers exactly as they appear in the text.

Diagram Completion:

Diagram completion is a question type in the IELTS reading test where you are presented with an incomplete diagram related to the passage you are reading. Your task is to complete the missing information in the diagram based on the information provided in the text. Here are three top strategies to effectively tackle diagram completion questions:

- Skim the Text First: Before you start completing the diagram, skim through the relevant section of the passage to get an overall understanding of the topic and the context of the information you need to add to the diagram.

- Pay Attention to Keywords: Focus on keywords, phrases, and any information that corresponds to the missing elements of the diagram. Be cautious about paraphrasing and synonyms. Sometimes, the text may use different words or phrases to describe the same information as in the diagram. Pay attention to variations and synonyms.

- Match the Information Carefully: When completing the diagram, match the information from the text to the corresponding parts of the diagram. Look for clear connections between what you read and what needs to be added.

True/False/Not Given:

True/False/Not Given questions are a type of IELTS Reading question that requires you to identify whether a statement is true, false, or not given in the passage.

- True statements are statements that are explicitly stated in the passage.

- False statements are statements that are explicitly contradicted in the passage.

- Not Given statements are statements that are neither explicitly stated nor contradicted in the passage

To answer True/False/Not Given questions, you need to be able to understand the passage and identify the key information. You also need to be able to distinguish between statements that are explicitly stated, contradicted, and not given.

Great work on attempting to solve the Sheet Glass Manufacture: The Float Process reading passage! To crack your IELTS Reading in the first go, try solving more of the recent Recent IELTS Reading Passages.

Also Check:

- Bright Children Reading Answers

- Dining Out & Electricity Account Payment IELTS Reading Answers

- Zheng He IELTS Reading Answers

- What Cookbooks Really Teach Us, Is There More To Video Games Than People Realize?, Seed Vault Guards Resources For The Future – IELTS Reading Answers

- Learn How to Solve 3 IELTS Passages for IELTS Reading in 40 minutes

Check More IELTS Reading Answers

Also Check :

Practice IELTS Reading based on question types

Start Preparing for IELTS: Get Your 10-Day Study Plan Today!

Recent Articles

Nehasri Ravishenbagam

Haniya Yashfeen

Haniya Yashfeen

Haniya Yashfeen

Post your Comments