IELTS Writing Task 1 Process Diagram: Tips, Vocabulary & Sample Answer

Confused by IELTS Process Diagrams? Learn how to ace Writing Task 1 with expert tips, essential vocabulary, updated sentence structures, and a Band 8+ sample answer—all in one place!

Table of Contents

IELTS Writing Prediction Questions for 2024

In the IELTS Writing Task 1 Academic section, you may be presented with different visual data types such as graphs, charts, maps, or process diagrams. Among these, process diagrams require you to describe how something works or how something is made—step by step.

This guide focuses on helping you tackle process diagrams efficiently, with tips, vocabulary, and sample structures to elevate your IELTS Writing band score.

What Is a Process Diagram in IELTS Writing Task 1?

A IELTS Writing Task 1 Process Chart or Diagram is a type of question where you describe a series of events or stages that happen in a process. There are two main types of processes:

- Manufacturing Process (MP) – Involves human intervention or machinery (e.g., brick-making, glass recycling).

- Natural Process (NP) – Involves naturally occurring cycles (e.g., the water cycle, life cycle of a frog).

Voice Usage:

- Use passive voice for manufacturing processes, since the focus is on the action, not the actor.

- Use active voice for natural processes, since natural subjects like animals, water, or the sun usually perform actions themselves.

How to Write a Process Diagram Report: Step-by-Step

1. Introduction

Start your report with one sentence that paraphrases the question.

Useful phrases:

- The diagram illustrates the process of…

- The picture describes how…

- The chart shows the steps involved in…

Example:

The diagram below shows how the Australian Bureau of Meteorology collects up-to-the-minute weather information to produce reliable forecasts.

➡ The figure illustrates the process used by the Australian Bureau of Meteorology to forecast the weather.

2. Overview

Provide a summary of the entire process without listing individual steps. Mention the total number of stages and the beginning and ending points.

Example:

Overall, the process consists of eight stages, beginning with the collection of raw materials and ending with their delivery to retail outlets.

3. Body Paragraph(s): Description of Stages

Describe the process logically from beginning to end. Use sequencing and linking words to guide the reader through the process.

Useful Linking Words & Phrases

The following are some useful linking words and phrases that you can use while writing the task 1 answers:

➤ Adverbs for Sequencing

- Firstly / To begin with / Initially

- Secondly / Next / Then / After that

- Subsequently / In the following stage

- Finally / Eventually / At the last step

Example:

To begin with, clay is dug up from the ground. Next, it is placed on a metal grid to filter out large rocks.

➤ Prepositions of Time/Stage

- At the beginning of the process

- At the end of the cycle

- In the next stage

- During the final stage

➤ Conjunctions for Complex Sentences

-

When / Once / As soon as / While / Whereas

-

Once the clay has been filtered, it is transported by conveyor belt to the rollers.

-

-

Before / After + gerund or clause

-

After shaping, the bricks are dried in a kiln.

-

-

Where / From where / After which

-

The bricks are moved to a cooling chamber, where they are stored for two days.

-

Enroll for IELTS Online Classes to Boost your IELTS Writing Skills!

Vocabulary for Describing Process Diagrams

Here’s a categorized list of IELTS Vocabulary for better clarity and variety in your writing:

1. Verbs Commonly Used in Processes

- Is transported / Delivered / Moved

- Is produced / Generated / Created

- Is filtered / Heated / Cooled

- Is packed / Stored / Delivered

2. Useful Nouns

- Process / Stage / Step / Phase

- Component / Substance / Element

- Equipment / Machine / Chamber / Kiln

Sentence Structures to Use

Using a variety of sentence structures improves coherence and shows grammatical range.

1. X (diagram/chart) shows how + clause

The diagram shows how electricity is generated using solar panels.

2. X (diagram/chart) + illustrates/describes + noun

The diagram illustrates the life cycle of a butterfly.

3. X (diagram/chart) provides/gives information about…

The diagram provides information about how bricks are manufactured.

Boost your IELTS Writing Task 1 score by signing up for an Expert Session today!

Sample IELTS Writing Task 1 Process Diagram Answer

Task Prompt:

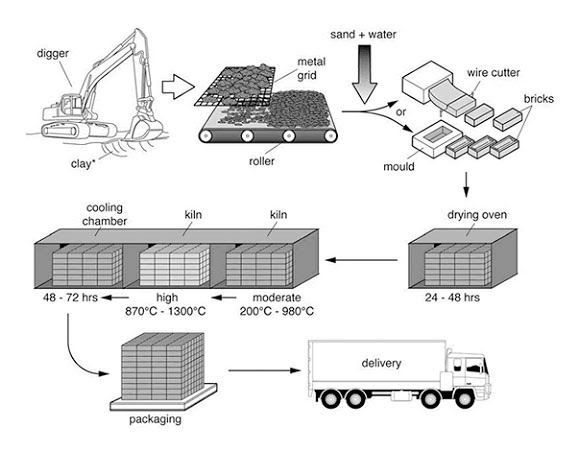

The diagram below shows the process used to manufacture bricks for the building industry.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Write at least 150 words.

Strategy to apply:

- Paraphrase the prompt in the intro

- Write an overview (e.g., "Overall, the process includes seven stages…")

- Describe each step sequentially

- Use linking phrases and passive voice

Sample Answer:

The diagram illustrates the process by which bricks are produced for the construction industry. Overall, the process consists of seven main stages, beginning with the extraction of clay and culminating in the delivery of finished bricks.

To begin with, clay is dug up from the ground using a large digger. The clay is then passed through a metal grid, which breaks it into smaller pieces, and a conveyor belt carries the refined material to a roller, where it is further crushed and shaped. Afterward, water and sand are added, and the mixture is shaped into bricks using either a wire cutter or molds.

Following this, the bricks are placed in a drying oven for 24 to 48 hours. They are then fired in a kiln at a moderate temperature (200–980°C) and subsequently at a higher temperature (870–1300°C). After being heated, the bricks go through a cooling process that lasts about 48 to 72 hours. Finally, the finished bricks are packaged and delivered for use in the building industry.

Common Mistakes to Avoid

Here are some common mistakes to avoid while writing IELTS Writing Task 1 answers:

- Writing in bullet points instead of full sentences

- Forgetting the overview

- Using active voice in manufacturing processes

- Describing the diagram like a narrative or story

- Including personal opinions or reasons

Tip: Practice by choosing various process diagrams from past IELTS tests. Time yourself for 20 minutes and review your work for structure, vocabulary, and IELTS Grammar.

Want feedback on your IELTS Writing essay? Submit your IELTS Writing Essay for evaluation today!

Describing a process diagram might seem tricky at first, but with the right strategy, vocabulary, and practice, it becomes manageable. Focus on clarity, sequencing, and IELTS Grammar to achieve a high IELTS band score. Use passive voice for man-made processes and active voice for natural ones. Keep practicing, and you’ll be ready to ace your IELTS Writing Task 1 with confidence!

Also check:

- IELTS Academic Writing Task 1 Tips, Strategies and Criteria

- IELTS Writing Answer sheet

- IELTS Writing Task 1: Map Vocabulary

- IELTS Writing Task 1 Connectors

- Highly Effective Paraphrasing Techniques for IELTS Writing Test

- IELTS Task 1 Pie Chart Strategies, Tricks, and Sample Answers

- Cohesive Devices in IELTS Writing: Meaning, Examples & List

Frequently Asked Questions

How to attempt an IELTS process diagram essay?

How is Grammar and Vocabulary important when writing the process diagram essay?

Can contractions or idioms be used for describing process diagrams in the IELTS Writing Task 1?

What words and phrases to avoid in the process diagram essay?

Is it always necessary to paraphrase the question in the process diagram of IELTS Academic Writing Task 1?

Practice IELTS Writing Task 1 based on report types

Proven tips to score Band 9 in IELTS Writing

Recent Articles

Nehasri Ravishenbagam

Nehasri Ravishenbagam

Kasturika Samanta

Post your Comments

14 Comments